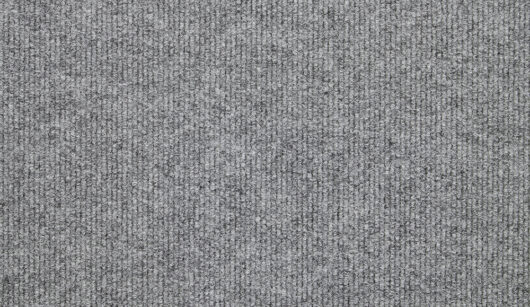

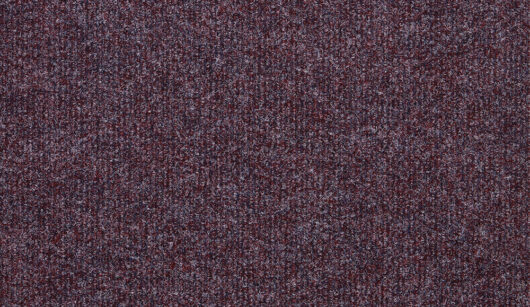

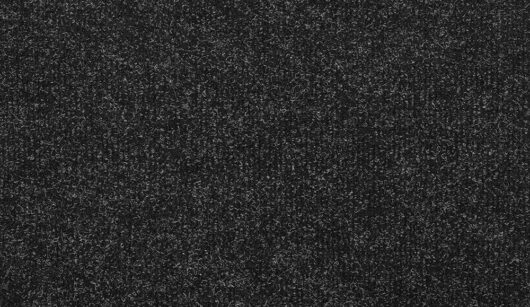

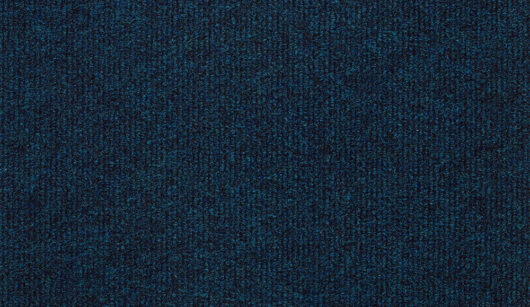

Ribbed Needlefelt Carpet Tiles

Tackle the toughest environments with our collection of ribbed needlefelt carpet tiles. These industrial strength tiles feature a unique ribbed surface that provides excellent grip and outstanding durability in the most demanding conditions.

The needlefelt construction creates an exceptionally hard wearing surface that withstands heavy foot traffic, wheeled equipment, and constant use. The distinctive ribbed pattern helps hide dirt and wear while providing slip resistance for safer walking surfaces.

Perfect for warehouses, workshops, retail spaces, and high traffic commercial areas where standard carpet tiles simply won't cope with the demands of daily use.

12 products

What are ribbed needlefelt carpet tiles?

Ribbed needlefelt carpet tiles combine the manufacturing process of needlefelt with a distinctive ribbed surface pattern. The needlefelt construction involves mechanically bonding synthetic fibres together using thousands of barbed needles, creating an incredibly dense and durable surface.

The ribbed pattern runs across the surface of each tile, creating raised lines that provide texture and visual interest. This surface design serves both practical and aesthetic purposes, offering improved grip while helping to disguise everyday wear and dirt.

Benefits of ribbed needlefelt carpet tiles

Outstanding durability

The needlefelt manufacturing process creates one of the toughest carpet surfaces available. These tiles can handle heavy machinery, constant foot traffic, and daily wear that would quickly damage other carpet types. The dense fibre structure resists crushing and maintains its shape even under extreme conditions.

Slip resistant surface

The ribbed pattern provides natural grip that helps prevent slips and falls, making these tiles safer in wet or dusty conditions. This makes them particularly valuable in industrial settings, loading bays, and areas where safety is a primary concern.

Low maintenance requirements

The robust construction and textured surface hide dirt and minor damage exceptionally well. Regular sweeping or vacuuming is often sufficient to keep these tiles looking presentable, reducing cleaning costs in commercial environments.

Where to use ribbed needlefelt carpet tiles

These tiles excel in the harshest commercial environments where other flooring materials struggle to cope. Warehouses, factories, loading areas, and workshop spaces benefit from their exceptional durability and practical performance.

Retail environments with heavy footfall, such as shop entrances, corridors, and back of house areas, also suit ribbed needlefelt tiles. Exhibition halls, conference centres, and temporary event spaces appreciate their ability to withstand intensive use over short periods.

Construction and performance features

The needlefelt process creates a non woven fabric where synthetic fibres are mechanically bonded rather than woven or tufted. This construction eliminates the backing systems used in traditional carpet tiles, creating a solid, stable surface throughout the entire thickness.

The ribbed surface pattern typically runs in parallel lines across each tile. This directional pattern can be used to create interesting visual effects when tiles are laid in different orientations, while the raised ribs help channel dirt and debris away from foot traffic areas.

Choosing ribbed needlefelt carpet tiles

Consider the specific demands of your environment when selecting these tiles. Heavier weight options provide maximum durability for the most demanding situations, while lighter versions suit areas with moderate but consistent traffic.

Colour selection affects both appearance and practicality. Darker colours and mixed tones hide dirt and staining most effectively, while lighter colours can help brighten industrial spaces that may lack natural light.

Installation and replacement

The dense, stable construction of needlefelt tiles makes them suitable for installation over most existing hard surfaces. Their weight and stability mean they often stay in place without adhesive, though high traffic areas may benefit from minimal fixing.

Individual tiles can be replaced when they reach the end of their working life, though the exceptional durability means replacements are needed far less frequently than with standard carpet tiles.

Maintenance and cleaning

The robust nature of ribbed needlefelt carpet tiles makes maintenance straightforward. Regular sweeping removes loose dirt and debris, while occasional vacuuming with an industrial machine keeps the surface clean.

The synthetic fibres resist most stains and can withstand stronger cleaning agents when necessary. The textured surface helps hide minor marks and wear, keeping floors looking acceptable even in demanding conditions.

Cost effectiveness in commercial use

While ribbed needlefelt carpet tiles may cost more initially than basic options, their exceptional lifespan makes them highly cost effective in demanding environments. The reduced replacement frequency and minimal maintenance requirements provide excellent value over time.

The ability to replace individual tiles rather than entire floor areas adds to their economic appeal, particularly in commercial settings where minimising disruption is important.

What our customer say about us

Related guides

Looking for new flooring, or re-styling a home but not sure where to start?

Check out our guides to find the answers to your questions.